| Availability: | |

|---|---|

| Quantity: | |

HPBL3000

ZHIBI

Summary

220VAC BL drives is a powerful driver designed by zhibi Technology independence which is assorted with the advanced motion control industrial. The drives adopt the latest DSP specialized for motor as the core technical matched with high speed digital logic chips and high quality power module. It gets the advantage on highly integration, small volume, well protection, high reliability etc. This drives can provide: panel speed adjust command, external simulative voltage, external potentiometer, pulse width speed adjust etc.

The main function of the drive is as follows:

●Choose a variety of speed adjustable, including input voltage setting, drive's internal speed setting,

communication interface setting etc.

●Complete isolation of electric supply, and Hall signal interface, guarantee of security.

●Digital display panel, abundant display content settings, abundant feature setting.

●The drive device of automatic protection, automatic control of current, with undervoltage and overvoltage, blocking and hall fault lamp protection function.

●The standard series can provide 2 times or even higher short-term overload current, different products with different supply.

Product features:

1. System Characteristic

Input Voltage: 110/220/380VAC, 50/60Hz

Continuous Output current: 12A

Max. Output current: 30A

Working temp.: 0~+45°C

Storage temp.: -20~+85°C

Working & storage humidity: <85% no frosting

Structure: wall-mountable box type

Dimension:L180 x W85 x H190mm

2. Basic Characteristic

Cooling: Radiator

Control terminals: Isolation

Protection: Over load, over heat, over speed, over voltage, lost voltage will cause the power abnormity

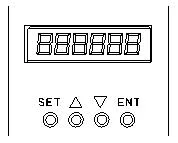

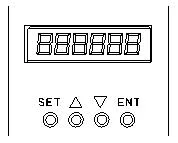

Panel: 6 digit LED display, 4 digit keypad operation

Terminal Function Specification

| No. | Terminal Name | Signal | Function |

| 1 | L1(L)(R) | Power input of main circuit | Main circuit power input terminal AC220V 50Hz, Connect L1 and L2 while using single phase voltage 220V |

| 2 | L2(N)(S) | ||

| 3 | L3(T) | ||

| 4 | P | High voltage DC bus line terminal | DC bus line terminal in driver, rated power 315V, Part of the products are built in brake resistance ,When using external brake resistance, connect it with P,B2. NOTE !!! Can not simultaneously access P and B1 |

| 5 | B1 | High voltage DC bus negative terminal | |

| 6 | B2 | External brake resistance | |

| 7 | U | Output | The motor output terminals must be connected with U,V,W one-to- one. Attention: do not reverse the motor by exchange 3 phase terminals, it is completely different with asynchronous motor |

| 8 | V | ||

| 9 | W | ||

| PE | Protection | The release way is supplied for protection motor and drive when current leakage |

3) Parameters setup

3.1 Parameters P1

This series characteristics are used to set up some functions by clients self, they can be self-adjust according to clients' different demand. They are operation functions, have no relation with fundamental characteristics of driver.

Parameter P1

| Parameter Name | Parameter No. | Set numerical range | Factory default | Function specification |

| Display optional | P1.0 | 0~9 | 0 | 0: Display real speed 1: Display DC voltage of main circuit 2: Display external analog input 3: Display motor current 4: Display driver's real-time power 8: Duty ratio 9: Preserve |

| Internal running speed | P1.1 | 0~9999 | 2000 | When choose internal speed, the data will decide motor's speed(view P1.2) |

| Choose signal sourcing of speed | P1.2 | 0~2 | 1 | 0: Internal instruct speed (P1[0] is internal speed, when motor running, to up speed , to reduce speed) 1: Analog input, using CN2 signal of 7 pin SV signal as motor's speed. 2: Communication order control (Temporarily unavailable) |

| Direction setting | P1.3 | 0~1 | 0 | 0: CW 1: CCW |

| Choose signal sourcing of start-stop | P1.4 | 0~2 | 1 | 0: Button by hand control(ENT is start-stop, SET is reverse motor, +/- is for up and reduce speed) 1: External terminal control: using 4pin signal of CN2 to start and stop motor 2: Communication order control |

| Pole pairs of motor | P1.5 | 0~99 | 2 | If the setting is not right, it will lead to the display of the speed and the actual speed does not match attention: pole pairs=pole/2 |

| Driver location | P1.6 | 0~255 | 1 | The driver location when Using communication to control motor |

| Speed scale factor | P1.7 | 0~99999 | 1520 | KP. Scale factor using for PID speed control (KP) |

| Speed integrating factor | P1.8 | 0~99999 | 320 | Integrating factor using for PID speed control(KI) |

| Accelerated speed | P1.9 | 1~60000 | 6000 | The parameters is proportional to accelerated speed (unit: rps), 1000 means accelerate 1000 turn per min. the real accelerated speed is based on loading of motor |

| Decelerated speed | P1.10 | 1~60000 | 6000 | Unit conversion / minute (RPM), when the analog input to the maximum value of the corresponding motor speed |

| Analog input speed range | P1.11 | 0~99999 | 3000 | |

| Analog input dead band | P1.12 | 0~3300 | 100 | The function is used to set input voltage when motor speed is 0 (unit: mV) |

| Manual operation to adjust speed equivalent | P1.13 | 1~999 | 1 | Use bottom to change the speed equivalent under internal speed type ( speed changed per press) |

| Recover default parameters | P1.14 | 0~1 | 0 | Set up 1 then quit setting, connecting the power again, all parameters will recover to default value. |

3.2 Control Panel Operation

Display instruction: total 6 digital tube shows "888888", the light most is the first and the lowest.

As picture on left, there are 4 keys on the panel,

"SET": press this key can enter or quite P1 setup menu

"▲"and "▼": "+"and "-",to choose the function and adjust the parameters.

"ENT": "confirmation" and "operation", when setting parameters, press this button to enter adjustment interface and jump. Under trial operation type, press ENT to start or stop motor.

Attention: The adjustment is forbidden if the adjusted value is larger than the maximum allowed, the bottom will be no response.

How to set parameters

Example:

Demand: set internal speed (P1.1) to 1000rpm/min

Operation step as below:

1.After connecting with power, display "H 0", the driver is standby, press "SET", will display"P0. 0", press "▲"until displayed "P0.6", press "ENT", display"00000", and the first of light most is flashing, press" ▲", change into "1", press "SET", display "P0. 6" . This step is to complete the P1 parameter set to unlock

2. Press "SET", display "P1 0", the driver is entering P1 setting state

3.Press "▲", until display "P1. 1"

4. Press "ENT", display "2000", and the first of light most is flashing

5. Press "ENT", until the flashing is moving to the fourth position

6. Press "▼", change into "1000"

7. Press "SET", display "P1. 1", the parameters had been set up and save automatic

8. Press "SET" again, back to standby state, display "H 0". Now, the new parameters adjustment had finished and take effect

Attention: 1. after adjustment, the driver need to connect with power again, then the new parameters will take effect

2. The parameters with "★" in the list can not been adjust when motor working

3. The adjustment is forbidden if the adjusted value is larger than the maximum allowed, the bottom be will no response

Summary

220VAC BL drives is a powerful driver designed by zhibi Technology independence which is assorted with the advanced motion control industrial. The drives adopt the latest DSP specialized for motor as the core technical matched with high speed digital logic chips and high quality power module. It gets the advantage on highly integration, small volume, well protection, high reliability etc. This drives can provide: panel speed adjust command, external simulative voltage, external potentiometer, pulse width speed adjust etc.

The main function of the drive is as follows:

●Choose a variety of speed adjustable, including input voltage setting, drive's internal speed setting,

communication interface setting etc.

●Complete isolation of electric supply, and Hall signal interface, guarantee of security.

●Digital display panel, abundant display content settings, abundant feature setting.

●The drive device of automatic protection, automatic control of current, with undervoltage and overvoltage, blocking and hall fault lamp protection function.

●The standard series can provide 2 times or even higher short-term overload current, different products with different supply.

Product features:

1. System Characteristic

Input Voltage: 110/220/380VAC, 50/60Hz

Continuous Output current: 12A

Max. Output current: 30A

Working temp.: 0~+45°C

Storage temp.: -20~+85°C

Working & storage humidity: <85% no frosting

Structure: wall-mountable box type

Dimension:L180 x W85 x H190mm

2. Basic Characteristic

Cooling: Radiator

Control terminals: Isolation

Protection: Over load, over heat, over speed, over voltage, lost voltage will cause the power abnormity

Panel: 6 digit LED display, 4 digit keypad operation

Terminal Function Specification

| No. | Terminal Name | Signal | Function |

| 1 | L1(L)(R) | Power input of main circuit | Main circuit power input terminal AC220V 50Hz, Connect L1 and L2 while using single phase voltage 220V |

| 2 | L2(N)(S) | ||

| 3 | L3(T) | ||

| 4 | P | High voltage DC bus line terminal | DC bus line terminal in driver, rated power 315V, Part of the products are built in brake resistance ,When using external brake resistance, connect it with P,B2. NOTE !!! Can not simultaneously access P and B1 |

| 5 | B1 | High voltage DC bus negative terminal | |

| 6 | B2 | External brake resistance | |

| 7 | U | Output | The motor output terminals must be connected with U,V,W one-to- one. Attention: do not reverse the motor by exchange 3 phase terminals, it is completely different with asynchronous motor |

| 8 | V | ||

| 9 | W | ||

| PE | Protection | The release way is supplied for protection motor and drive when current leakage |

3) Parameters setup

3.1 Parameters P1

This series characteristics are used to set up some functions by clients self, they can be self-adjust according to clients' different demand. They are operation functions, have no relation with fundamental characteristics of driver.

Parameter P1

| Parameter Name | Parameter No. | Set numerical range | Factory default | Function specification |

| Display optional | P1.0 | 0~9 | 0 | 0: Display real speed 1: Display DC voltage of main circuit 2: Display external analog input 3: Display motor current 4: Display driver's real-time power 8: Duty ratio 9: Preserve |

| Internal running speed | P1.1 | 0~9999 | 2000 | When choose internal speed, the data will decide motor's speed(view P1.2) |

| Choose signal sourcing of speed | P1.2 | 0~2 | 1 | 0: Internal instruct speed (P1[0] is internal speed, when motor running, to up speed , to reduce speed) 1: Analog input, using CN2 signal of 7 pin SV signal as motor's speed. 2: Communication order control (Temporarily unavailable) |

| Direction setting | P1.3 | 0~1 | 0 | 0: CW 1: CCW |

| Choose signal sourcing of start-stop | P1.4 | 0~2 | 1 | 0: Button by hand control(ENT is start-stop, SET is reverse motor, +/- is for up and reduce speed) 1: External terminal control: using 4pin signal of CN2 to start and stop motor 2: Communication order control |

| Pole pairs of motor | P1.5 | 0~99 | 2 | If the setting is not right, it will lead to the display of the speed and the actual speed does not match attention: pole pairs=pole/2 |

| Driver location | P1.6 | 0~255 | 1 | The driver location when Using communication to control motor |

| Speed scale factor | P1.7 | 0~99999 | 1520 | KP. Scale factor using for PID speed control (KP) |

| Speed integrating factor | P1.8 | 0~99999 | 320 | Integrating factor using for PID speed control(KI) |

| Accelerated speed | P1.9 | 1~60000 | 6000 | The parameters is proportional to accelerated speed (unit: rps), 1000 means accelerate 1000 turn per min. the real accelerated speed is based on loading of motor |

| Decelerated speed | P1.10 | 1~60000 | 6000 | Unit conversion / minute (RPM), when the analog input to the maximum value of the corresponding motor speed |

| Analog input speed range | P1.11 | 0~99999 | 3000 | |

| Analog input dead band | P1.12 | 0~3300 | 100 | The function is used to set input voltage when motor speed is 0 (unit: mV) |

| Manual operation to adjust speed equivalent | P1.13 | 1~999 | 1 | Use bottom to change the speed equivalent under internal speed type ( speed changed per press) |

| Recover default parameters | P1.14 | 0~1 | 0 | Set up 1 then quit setting, connecting the power again, all parameters will recover to default value. |

3.2 Control Panel Operation

Display instruction: total 6 digital tube shows "888888", the light most is the first and the lowest.

As picture on left, there are 4 keys on the panel,

"SET": press this key can enter or quite P1 setup menu

"▲"and "▼": "+"and "-",to choose the function and adjust the parameters.

"ENT": "confirmation" and "operation", when setting parameters, press this button to enter adjustment interface and jump. Under trial operation type, press ENT to start or stop motor.

Attention: The adjustment is forbidden if the adjusted value is larger than the maximum allowed, the bottom will be no response.

How to set parameters

Example:

Demand: set internal speed (P1.1) to 1000rpm/min

Operation step as below:

1.After connecting with power, display "H 0", the driver is standby, press "SET", will display"P0. 0", press "▲"until displayed "P0.6", press "ENT", display"00000", and the first of light most is flashing, press" ▲", change into "1", press "SET", display "P0. 6" . This step is to complete the P1 parameter set to unlock

2. Press "SET", display "P1 0", the driver is entering P1 setting state

3.Press "▲", until display "P1. 1"

4. Press "ENT", display "2000", and the first of light most is flashing

5. Press "ENT", until the flashing is moving to the fourth position

6. Press "▼", change into "1000"

7. Press "SET", display "P1. 1", the parameters had been set up and save automatic

8. Press "SET" again, back to standby state, display "H 0". Now, the new parameters adjustment had finished and take effect

Attention: 1. after adjustment, the driver need to connect with power again, then the new parameters will take effect

2. The parameters with "★" in the list can not been adjust when motor working

3. The adjustment is forbidden if the adjusted value is larger than the maximum allowed, the bottom be will no response

Home | Products | About Us | Application | Download | News | Contact Us